Shortly after I joined Progressive International in 2019, we set out to enter the reusable silicone bag space. Silicone bags were a growing market driven by the consumer desire to reduce plastic waste and growing concerns about microplastics in food. We set out to take a piece of it with the hopes of creating a new and differentiated product at a lower price than competition.

Competitive Landscape

Ziploc and similar are the standard. They’re low cost, and have very strong seals.

Stasher was the trailblazer and the market leader in the reusable silicone bag category. Their silicone bags were sold everywhere, and were well-reviewed. However they were not without some annoyances. The cleanability, relatively complex construction, and stiff silicone that could rip were all opportunities for us.

There were also various other reusable bags which used a separate rigid closure, or were made of plastic film but just more robust. All others were not as good as stasher’s for one reason or another.

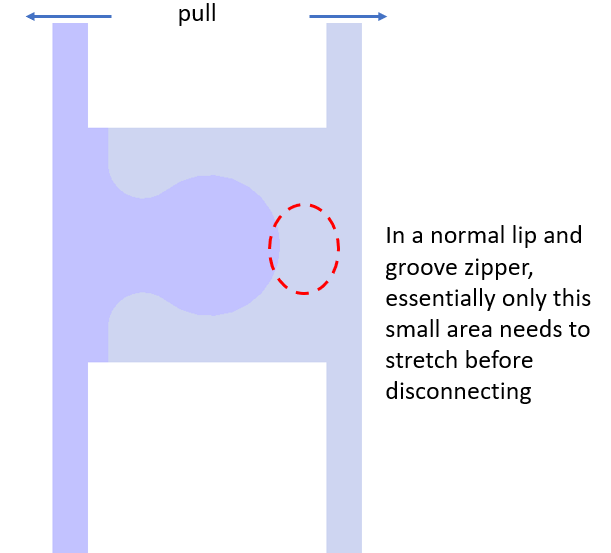

When testing silicone bags it was immediately obvious some seals are much better than others. Silicone is such a soft material that a simple lip and groove like a ziploc just barely holds together. In ziplocs, the zippers are made of extruded PP or PE. The female side and male side fit snugly with a snap fit creating the seal along the length of the opening.

Most silicone bags on the market had very weak seals and most didn’t even hold water. Some bags have thick lip-and-groove designs to compensate. However, this leads to expensive bags with stiff openings which rub on your hand as you reach in.

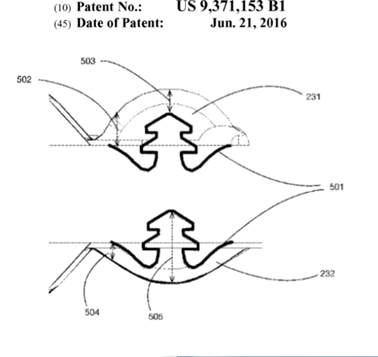

Stasher has taken a unique approach and their seal was the best. Rather than a single, thick, and sturdy lip-and-groove, they incorporate a design with multiple lips and grooves in a Christmas tree shape. Their patent claims that a big enough ratio is needed between the length the fluid must pass through to leak, and the straight line distance crossed.

After considering all the competition, we started the design process aiming to come in at a more competitive price point with the best product we could. The main design objectives were:

- Water tight seal

- Avoid Stasher patent

- Costs less than Stasher

- Invertible for cleaning in dishwasher

- Bag should stands up on its own for easy filling

- Molded in a single compression mold

Design Process

The zipper design was critical so we started there. The inherent problem with any lip and groove attachment is that the groove can relatively easily flex open. Only this small area of the groove needs to bend for it to detach. If you add too much material to this area it becomes better sealed but then the mouth of the bag becomes difficult to open. If you use a very hard silicone then the rest of the bag is no longer bag-like, it’s more of a rigid container.

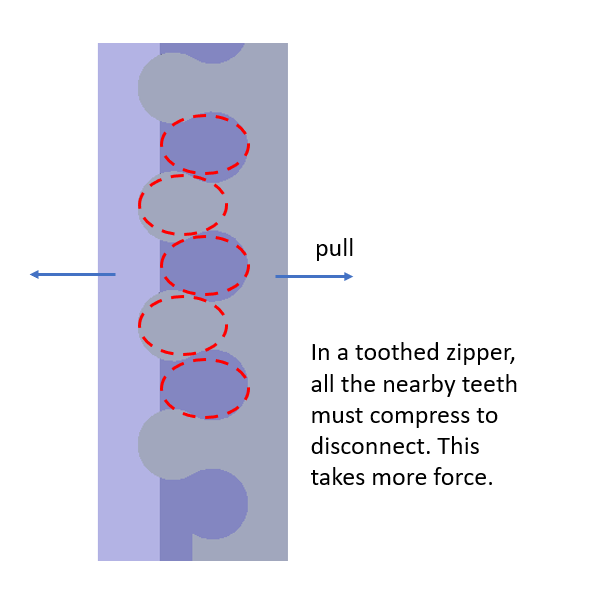

To get around this problem, the best solution is to separate the area that needs to be stiff from the area that needs to be flexible. It helps that compression molded silicone does not have the same constraints as extruded zipper seals. I proposed a toothed zipper style mechanism. To disconnect the teeth, all the teeth in the area need to deform and become elongated, which takes much more energy than bending a similarly sized groove open. Once the teeth are disengaged, the mouth of the bag can bend open easily because of the thin sections around each tooth.

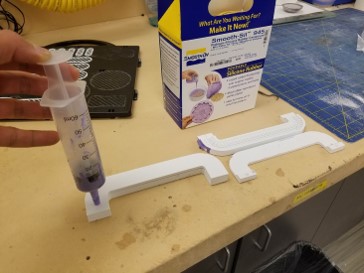

I made prototypes using the same techniques I learned when working on the robotic fish. We used RTV silicone injected with a syringe into a 3D printed mold. The pictured toothed prototype actually had two rows of teeth, with a lip & groove in between them. The double set of zipper teeth worked even better but it was deemed unnecessary since one row of teeth proved strong enough.

As design engineer it was also my responsibility to communicate frequently with the factory regarding the tooling design and to rigorously test off-tool samples. We navigated various other challenges including, ensuring oven-safe silicone temperatures, and conducting extensive dishwasher cycle testing.

The Final Products

The final product is the best on the market in my humble opinion. A stasher bag filled to capacity with water will burst with a light shake while Prokeeper’s will not. Because a toothed zipper is much stronger, we could use a lower durometer silicone compared to Stasher. Lower durometer silicone is actually more tear resistant than harder durometers so the bags are nearly impossible to rip. It’s invertible for cleaning in the dishwasher and the burst strength is the highest of any other silicone bags. The zipper is easier to clean than Stasher’s too since it has no sharp inside corners. We developed four sizes of bags for the first launch.

After launching the first few sizes we developed a slightly larger 2 sided zipper version. It’s much easier to get a sandwich into. The best part is you never have to get your hands dirty since you just peel back the sides like a banana. Personally I think this is the single best way to take a sandwich on the go.

A few years later we also expanded into boxes which we called Softboxes, and larger “standing bags”. These are useful for larger amounts of food and you can eat directly out of them. Such containers are not possible with regular lip-and-groove zippers because they simply aren’t strong enough to hold that much water.

The resulting silicone bags and Softboxes have achieved millions of dollars in sales through major retailers such as Target, Costco, and Pampered Chef. The project stands as an example of how thoughtful product design engineering can lead to enhanced user experiences and significant market success.

We were awarded a patent Flexible Container (US11505368B2) which protects against other competitors using the toothed zipper design.